Welcome to Materials Science and Technology!

Imagine scenarios where your car deforms in just the right way during an accident to protect you, or where a Canadian goose striking an aircraft at a speed of 300 km/h doesn’t lead to disaster. The MST research group, based in this remarkable building, is at the forefront of making these situations safer and more predictable. In addition to the MST, this facility also houses the research groups of Molecular Modeling, Soete Laboratory and Sustainable Materials Science.

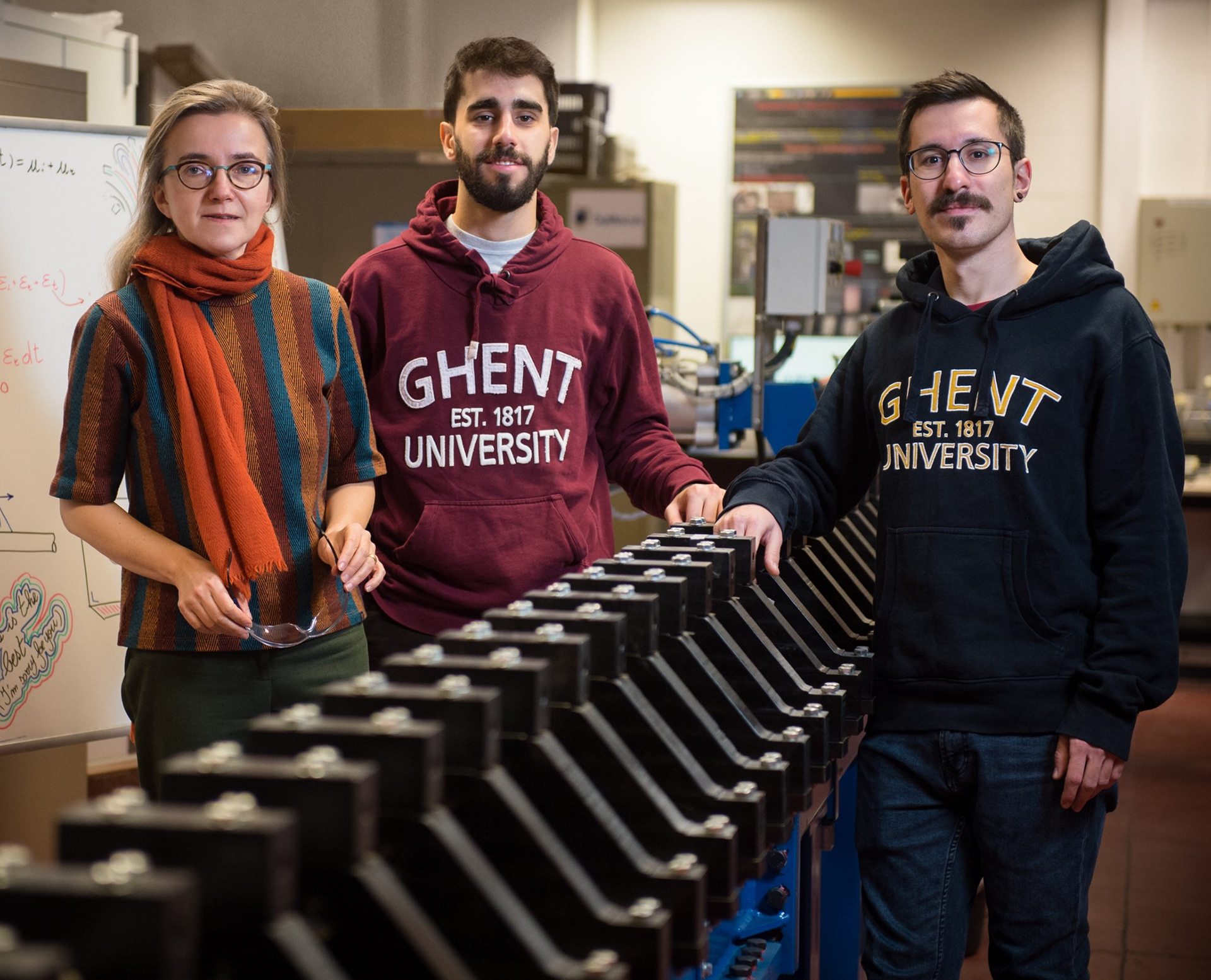

Soete Laboratory

At Soete Laboratory, we push the boundaries in fracture mechanics and tribology. As researchers, we are engaged in both experimental and numerical research on fatigue, fracture, friction, wear, reliability, and durability of machine parts and mechanical constructions. Do you have non-standard, complex, component-scale testing or numerical requirements? We at Soete Laboratory specialize in providing bespoke solutions to meet your specific demands.

Unlocking the full potential of materials

The Materials Science and Technology (MST) group conducts research in key areas of materials science, with a strong tradition of collaboration with industrial and academic partners worldwide.

Materials owe their mechanical properties as strength, formability or fatigue resistance to their internal structure at microscopic scale; in a way similar to the connection of physiological features of a living organism to the molecular configuration of its DNA genome. In the MST group the “materials’ DNA” is visualized with powerful electron microscopy (even with atomic resolution) and new models are developed to predict and improve material properties based on these observations.

Making Mobility and Aviation Safer

The MST group is committed to understanding how materials behave under various conditions, such as high speeds, severe pressure, and sudden impacts. A significant portion of their research, about 60%, is dedicated to mobility, focusing on testing vehicle crashes. Another 30% of their efforts are devoted to the aviation industry, for example, studying the impact of hail stones on aircraft turbines. The remaining 10% is reserved for various other challenges, allowing MST to explore a diverse range of materials and scenarios.

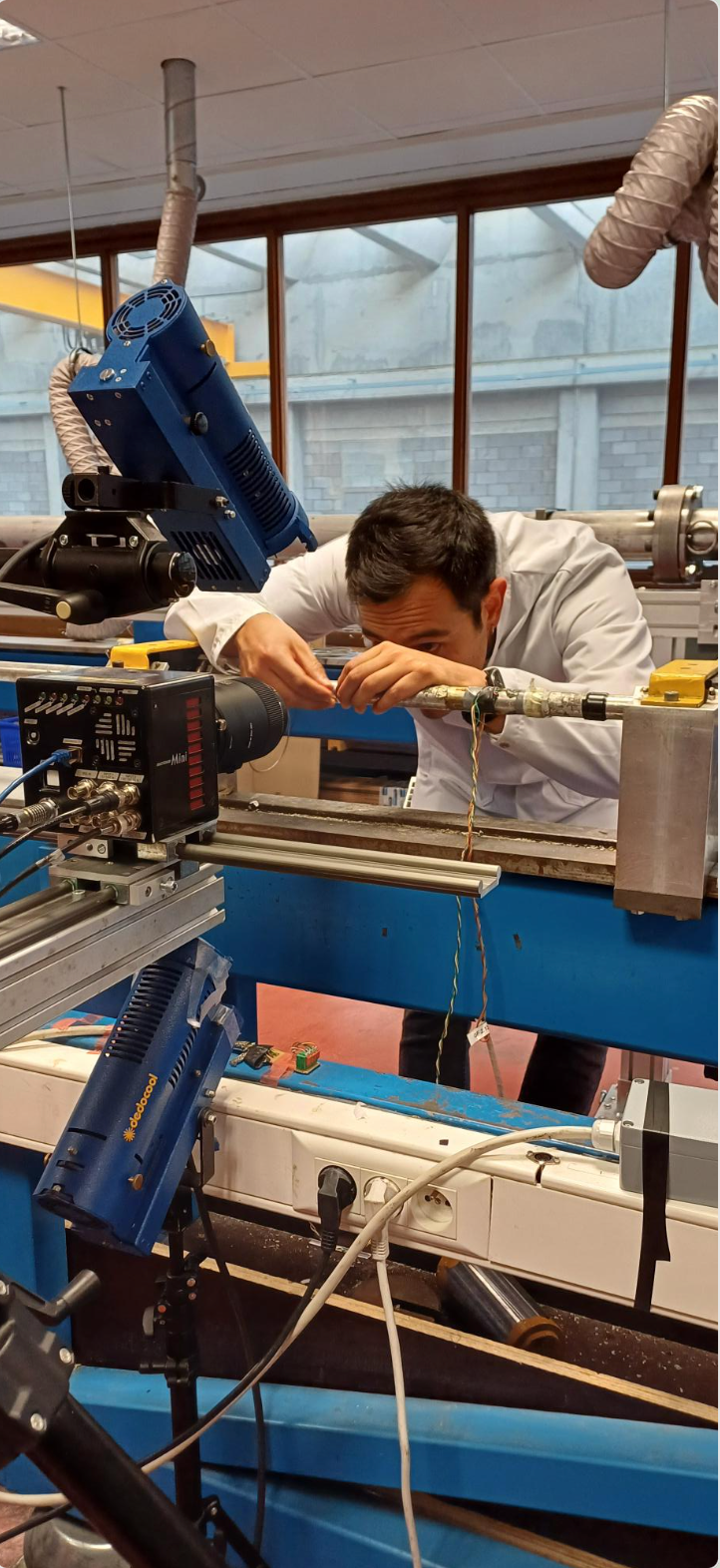

Simulating Real-World Conditions in the Lab

To achieve their research goals, MST simulates real-life scenarios in the lab using advanced equipment. For instance, they take small samples from objects like cars, buildings, or aircrafts and subject them to the forces they might experience in extreme impact cases.

This process might involve a pressure cannon accelerating object to well-above 100 km/h, generating a pressure wave that breaks a material in a fraction of a millisecond. High-speed cameras, capturing millions of frames per second, then capture how the material deforms and eventually fails under these conditions, providing detailed insights into its behavior.

© mst.ugent.be

© mst.ugent.be

© mst.ugent.be

The center for Molecular Modeling

The center for Molecular Modeling focuses on understanding and improving industrial chemical processes through computer simulations. They study what happens on the smallest scale, such as how molecules and atoms interact. This approach allows them to predict which materials and conditions work best without the need for endless trial and error. It’s particularly useful in designing new catalysts that speed up chemical reactions without being consumed in the process.